INFRA

INFRA

INFRA

INFRA

INFRA

INFRA

Shares of Taiwan Semiconductor Manufacturing Co. rose slightly today after it posted third-quarter profits and revenue that topped analyst expectations.

TSMC’s upbeat 2024 outlook was likely also a factor behind its stock market gains. According to Reuters, Chief Executive Officer C. C. Wei told investors that the company is expecting a “healthy growth year.”

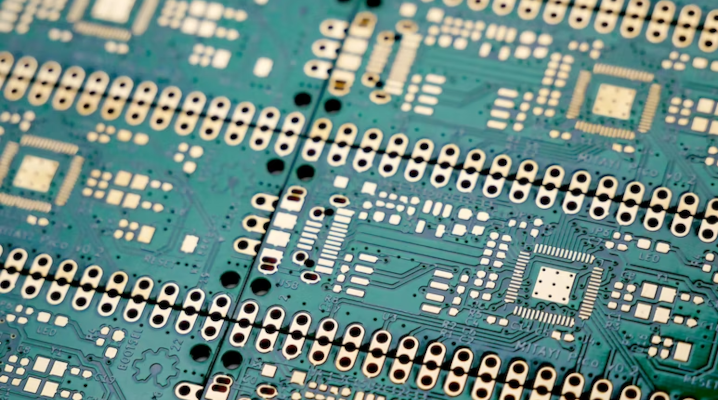

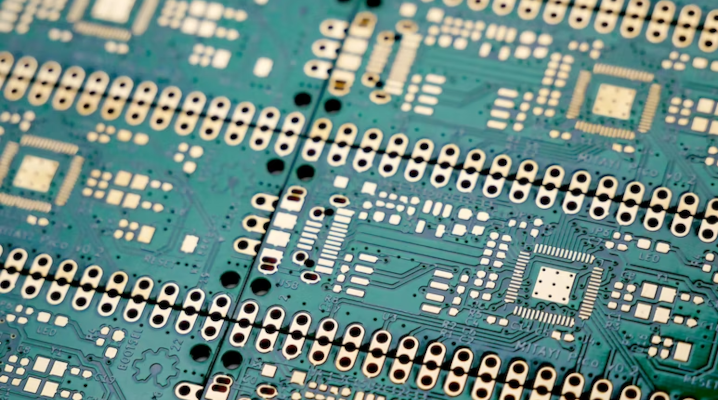

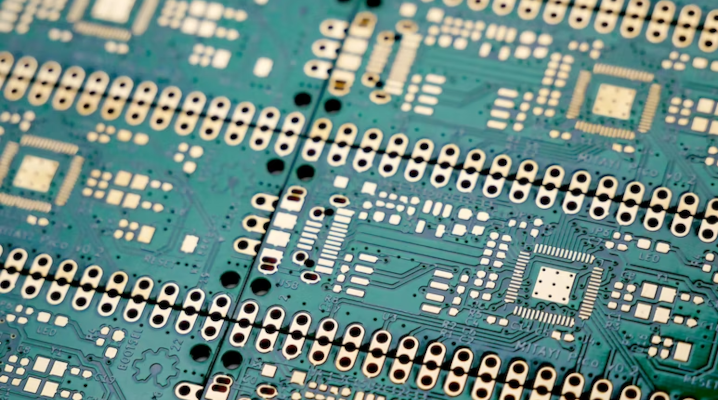

TSMC is the world’s largest contract chipmaker. Its customer base includes Apple Inc., Nvidia Corp., Advanced Micro Devices Inc. and a host of other tech giants. Its earnings are consequently an important gauge of worldwide chip demand.

The semiconductor industry is currently in the midst of a broad sales slowdown, which took its toll on TSMC’s third-quarter results. The company posted a net profit of 211 billion New Taiwan dollars, or $6.69 billion, for the three months ended Sept. 30. That’s 24.87% less than a year earlier, but higher than the NT$191.43 billion forecasted by analysts.

The higher-than-expected profit was partly the result of a sweeping cost-cutting initiative it rolled out earlier this year. Compared with the previous quarter, the chipmaker lowered capital expenditures by 13% to $7.1 billion.

TSMC is scaling back spending even as it pursues expensive long-term investments in new manufacturing technologies and fabs. Earlier this year, the company detailed plans to build a $2.9 billion chip packaging plant. It has also earmarked $40 billion for two cutting-edge fabs in Arizona and is working to bring a new two-nanometer process online.

The profit decline mirrored a slowdown in its sales. The chipmaker today reported quarterly revenues of NT$546.73 billion, or $17.28 billion, which represents a 14.5% decline from the same time a year ago. But TSMC still managed to top the consensus analyst estimate, which forecasted sales of NT$540.39 billion.

The chipmaker said that 42% of its third-quarter revenue came from its high-performance computing segment. This segment includes the H100 and A100 graphics cards TSMC makes for Nvidia, as well as other speedy data center chips. The company’s $2.9 billion plan to build a new chip packaging plant is partly a response to the surging demand for Nvidia’s graphics cards, which make extensive use of chip packaging components.

TMSC expects the current semiconductor slump to continue into the fourth quarter. Customers, the company said, are still working through their existing chip inventories and will therefore order fewer new processors. On the bright side, TSMC expects the slowdown to be partly offset by the rapid growth in AI chip orders.

The company’s forecasts suggest that chip demand outside the AI segment will start picking up next year. Reuters quoted Wei as saying that “we can expect 2024 to be a healthy growth year.” The executive reportedly added that the company expects to “do better than the overall industry.”

Beyond 2024, TSMC’s growth plan hinges in large part on its upcoming two-nanometer manufacturing process. The process represents one of the biggest-ever updates to the way the company makes chips. It’s expected to enter mass production in late 2025.

TSMC’s two-nanometer process will use a new transistor design known as a gate-all-around architecture. This design reduces leakage current, a phenomenon whereby some of the electricity that travels through a transistor “leaks” and goes unused. Reducing energy waste lowers processors’ power consumption.

TSMC’s two-nanometer process will also make it possible to more granularly customize processors for specific use cases. Thanks to their gate-all-around architecture, chips made using the process can be optimized for different power-efficiency and performance levels at the transistor level. This is done by varying the width of a transistor component called the channel that is used to move electricity inside a chip.

As part of its two-nanometer roadmap, TSMC also plans to update other aspects of its chip manufacturing workflow. In a traditional processor, the miniature wires that deliver power to transistors are placed above those transistors. In TSMC’s two-nanometer chips, the wires will be placed below the transistors to improve performance.

Other chipmakers are also investing heavily to upgrade their manufacturing capabilities. Last June, Samsung Electronics Co. Ltd. started mass-producing three-nanometer processors. Intel Corp., for its part, has set a goal of rolling out five new chip manufacturing processes in four years.

THANK YOU